60 Years of God’s Grace & Goodness

A legacy founded on Biblical principles and stewarded with a deeper purpose.

SDMyers celebrates 60 years at the forefront of transformer maintenance and reliability, shaping the industry from the early developments of transformer oil testing to modern maintenance best practices. However, the purpose has always been about more than just transformers. Founded on biblical principles, valuing people, stewarding resources, and influencing communities, see how our dedication to these values has and continues to make a difference in the world.

Scroll Down

From humble beginnings in 1965 to a trusted leader in electric reliability and transformer maintenance, our journey is defined by God’s faithfulness and the stewardship of those committed to something greater than economic success. As a Good Place company, we believe our work is a response to God’s grace and goodness, not a reflection of our own strength or intelligence. What you read here and the people you see in these images are a result of our Legacy Builders (the people, customers, and vendors) working to make the world a better place—a good place.

1960s

1960s

Early Research into Transformer Oil Processing

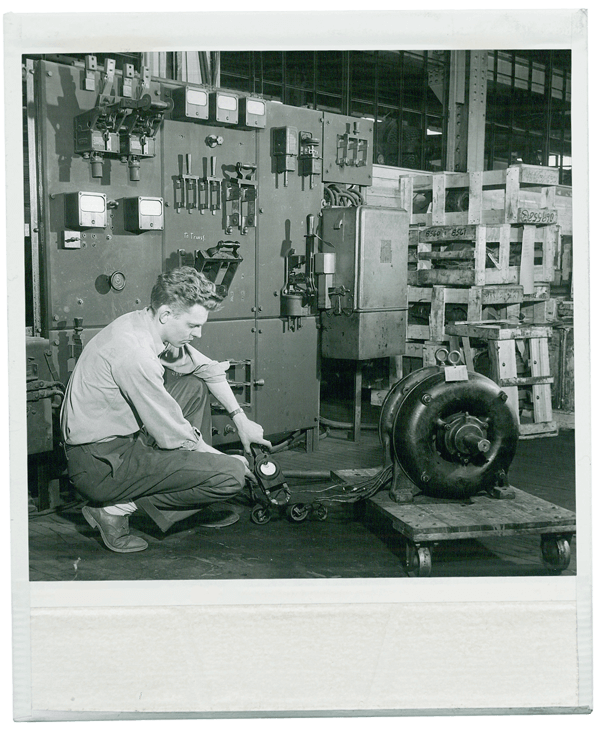

Stanley D. Myers—founder of SDMyers—graduated from the University of Akron with a degree in Electrical Engineering. After serving his country in World War II, Stan went to work at an electric supply company that also performed maintenance and service, such as rewinding electric motors and small transformers.

While working there, Stan became curious about the quality of transformer oil. He conducted research and discovered that transformer oil degraded over time, impacting the reliable life of the equipment. He believed you could extend transformer life by processing or “cleaning” the oil. However, the company he worked for at the time was not interested in pursuing this idea due to its small market potential.

1960s

1960s

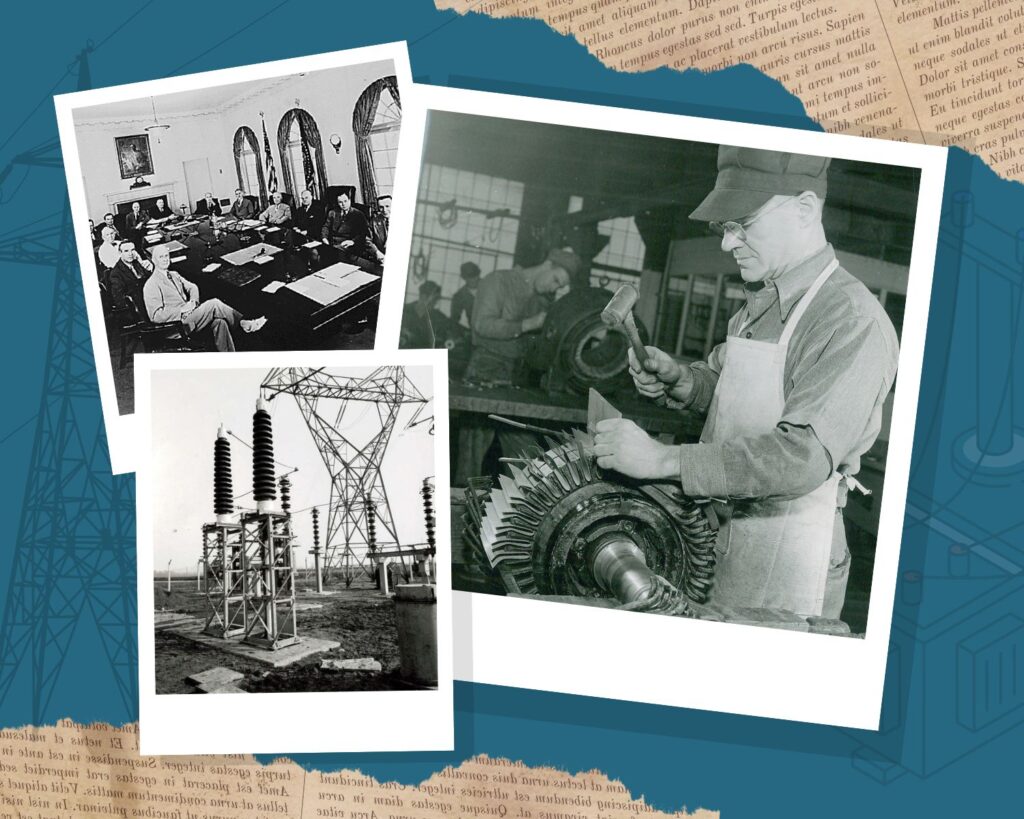

World EventPost-War Advancements in Transformers

The need for reliable power in the postwar 1950s and 1960s led to major innovations in transformer efficiency, insulation materials, and oil-cooled designs. The energy crisis during the decades after WWII required the expansion of power grids, which supported the rise of computing, modern appliances, and telecommunications. As energy demands grew, transformer reliability was at the center of it all.

1964

1964

Work at Akron Canton Electric Supply (AC Supply)

To process transformer oil, Stan Myers formed a partnership with another electrical engineer. Together, they designed, assembled, and operated a Re-Refiner (or a Reclaimer) to refine the oil to “like-new” properties. Noticing the various conditions of the oil in transformers, Stan believed that the oil condition was a significant factor in the transformer’s reliability. He continued to study and research this subject to improve oil processing. Through his curiosity, research, and intuition, Stan was about to embark upon an entrepreneurial risk.

1965

1965

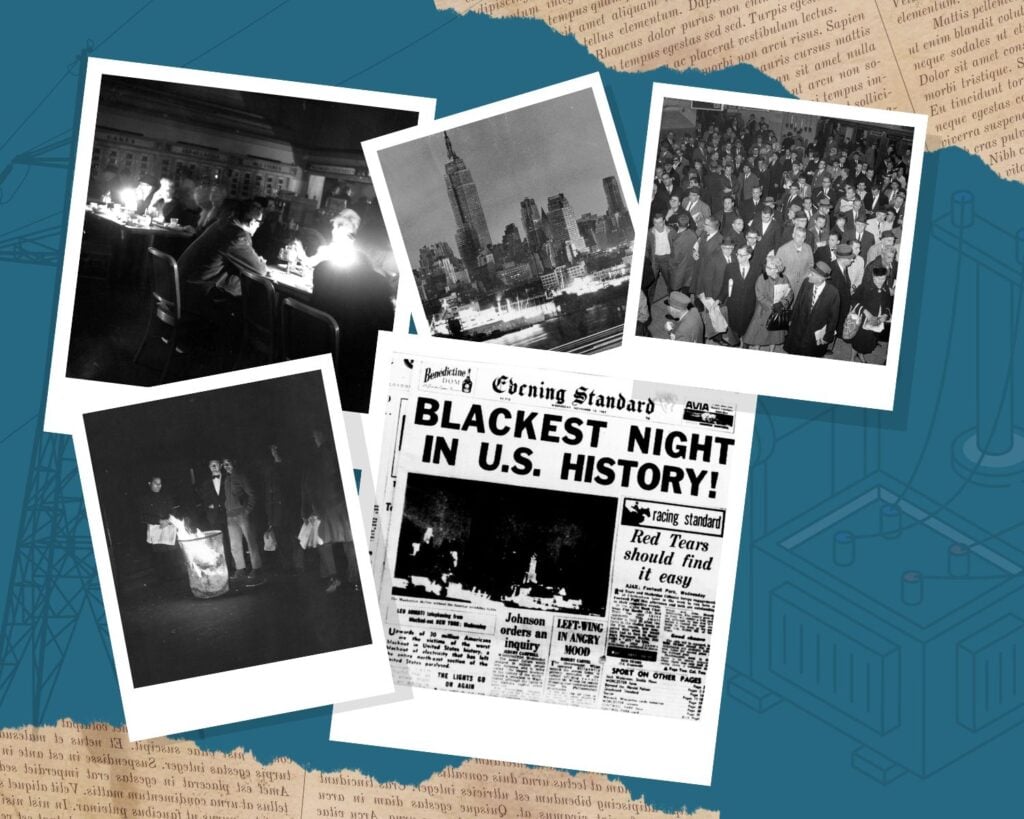

World EventNortheast Blackout of 1965

The Northeast Blackout of 1965 was a massive power failure that affected around 30 million people across eight U.S. states and parts of Ontario, Canada. Triggered by a faulty protective relay near the Niagara Generating Station, the outage cut power to major cities like New York, Boston, and Toronto.

The event exposed critical vulnerabilities in the electric grid’s design and distribution. Highlighting the need for electric power reliability, leaders saw how a single equipment failure could cascade across an entire region without safeguards in place. In response, utility companies and regulators launched sweeping reforms and new standards to ensure more resilient, coordinated, and fail-safe electric power systems.

1965

1965

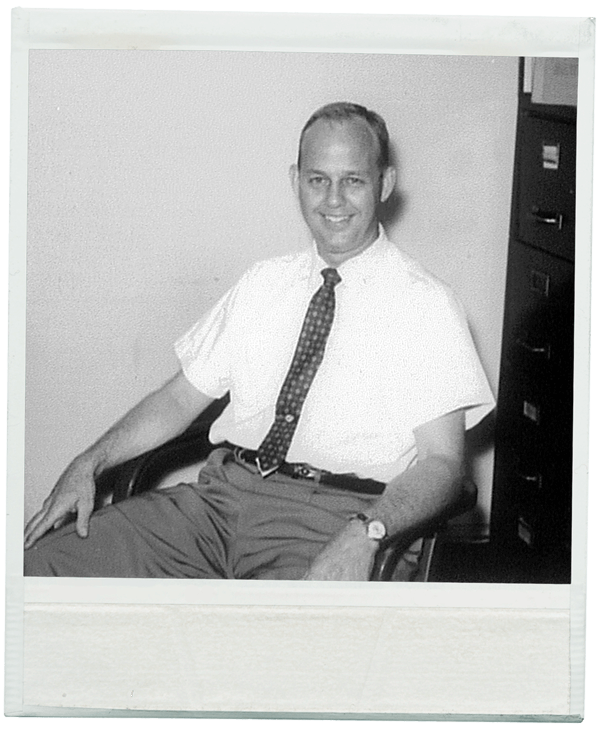

Founding of SDMyers

With an entrepreneurial vision to revolutionize transformer maintenance, Stan Myers launched his own business, called SDMyers, to maximize oil processing technology. The founding of SDMyers in 1965 marks the beginning of our legacy in helping customers understand the health of their transformers and maximize safety and reliability.

From the beginning, Stan Myers put the needs of his customers first. This customer-centric approach established the culture and DNA of the company that still exists to this day. The mantra of “helping customers spend the least in the short term to see the longest-term value” has impacted thousands of organizations with over half a million transformers.

1965

1965

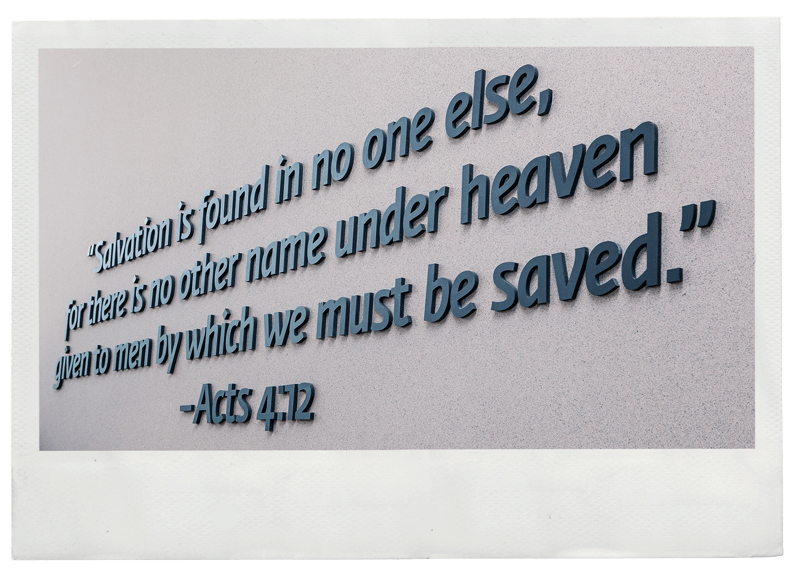

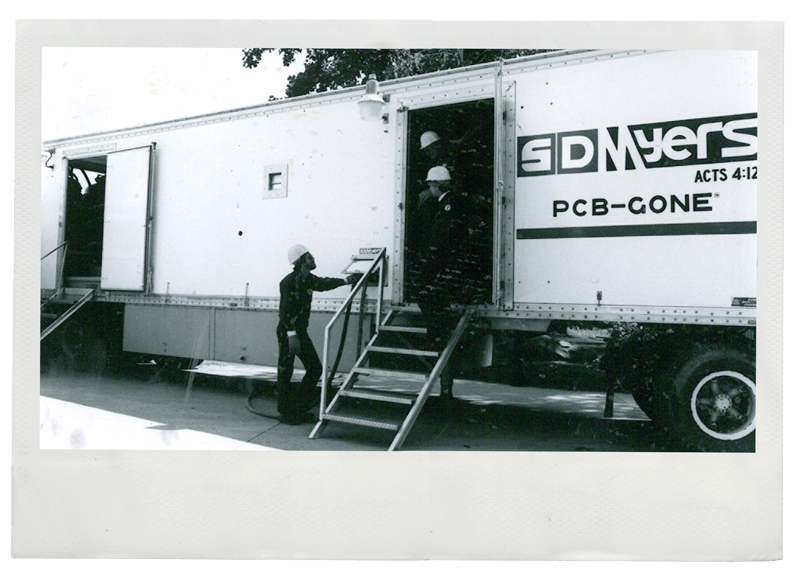

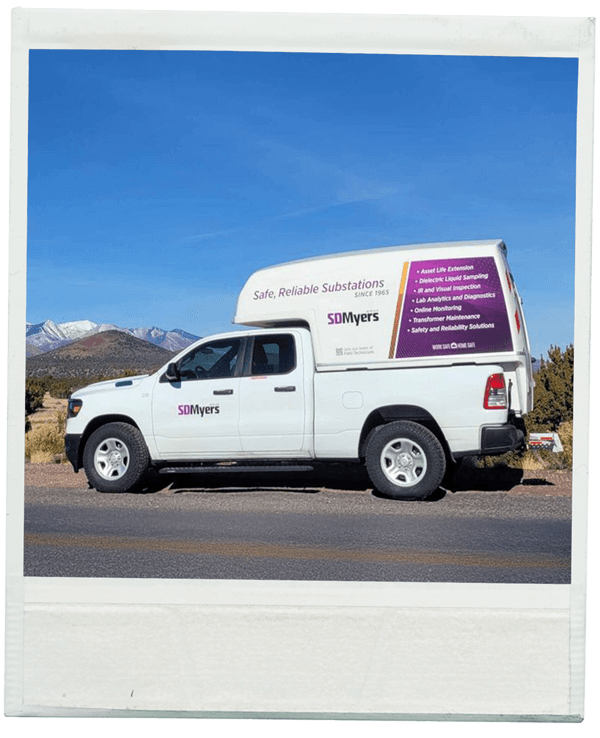

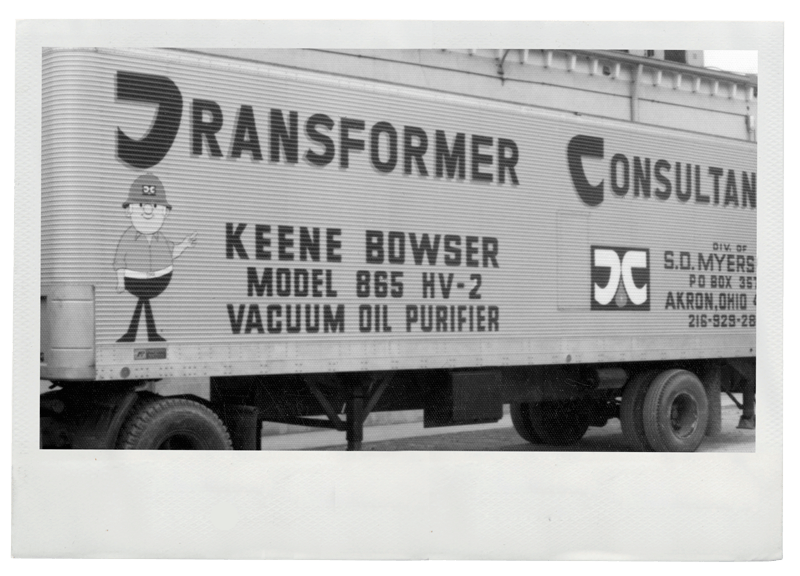

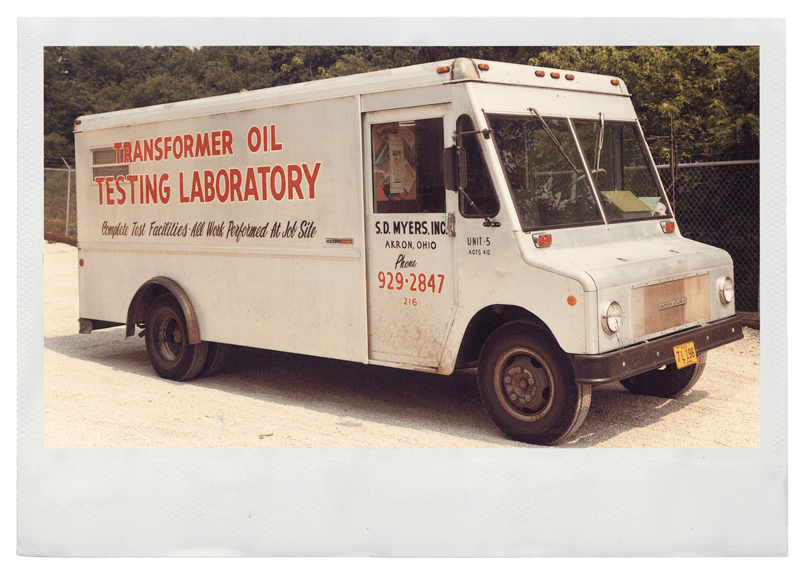

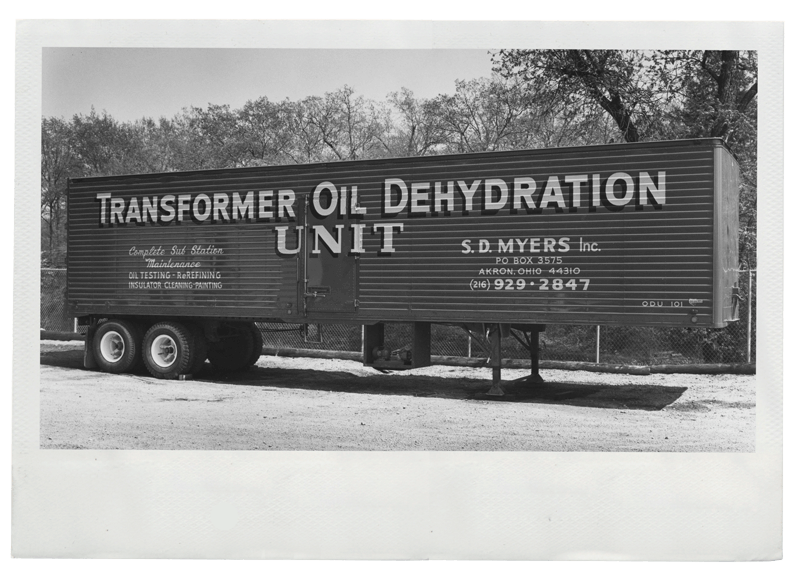

Acts 4:12 Included on Trucks and Flyers

Since its founding in 1965, SDMyers has featured Acts 4:12 in its marketing materials, flyers, and on the side of its trucks—a reflection of founder Stan Myers’ vision to build a company rooted in biblical values. The verse, which proclaims salvation through Jesus Christ alone, symbolizes Myers’ desire to never be ashamed of the Gospel of Jesus Christ. For Stan, the company was more than a transformer maintenance service—it was a platform to live out his faith, promote truth, and make the world a better place—a good place.

This foundational commitment continues to shape SDMyers’ culture, mission, and service. In the 1980s, Acts 4:12 became a permant part of the brand by being included in the SDMyers logo.

1965

1965

Re-Refiner Rig Designed

Stan Myers designed the “Re-Refiner” rig, one of the first pieces of equipment to remove moisture, gas, acids, and sludge from oil while transformers remained energized. With Stan leading his own company, he was able to design a more effective and versatile Reclaimer. The effectiveness of the new unit enabled it to re-dissolve sludges that were deposited in the transformer. By re-dissolving sludges, this unit not only cleaned the oil but also cleaned the interior of the transformer, thereby extending its lifespan.

1969

1969

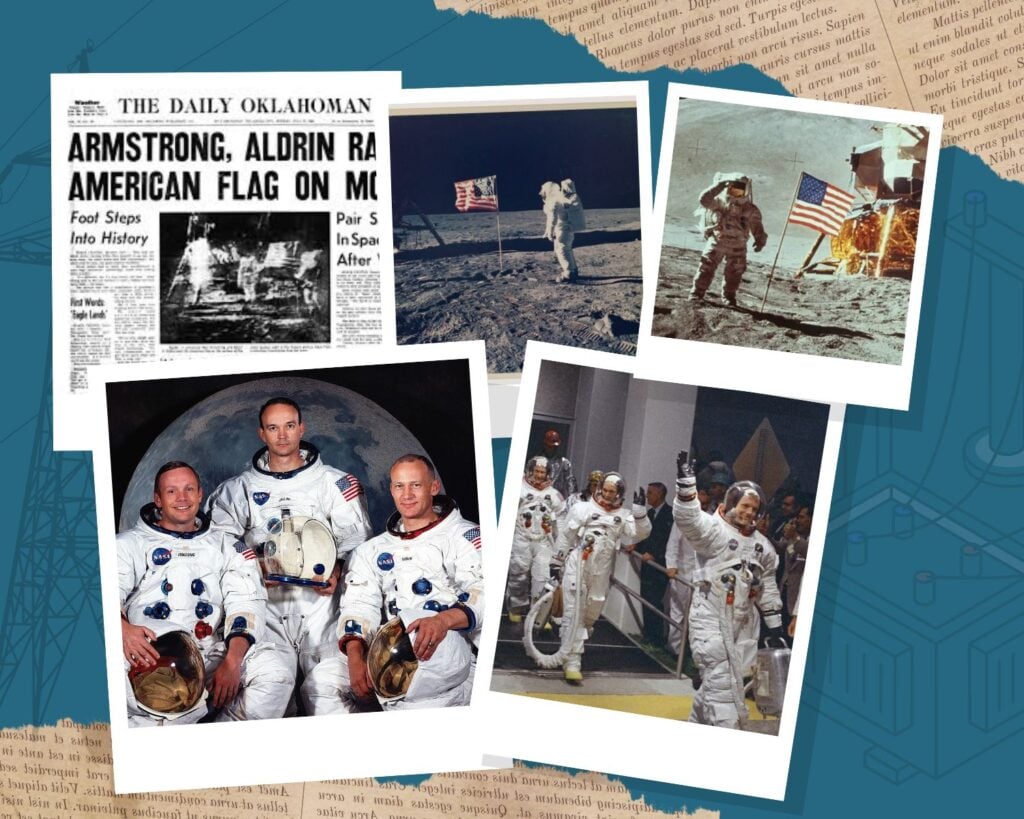

World EventApollo 11 Moon Landing

On July 20, 1969, NASA’s Apollo 11 mission made history when astronauts Neil Armstrong and Buzz Aldrin became the first humans to land on the Moon, while Michael Collins orbited above in the command module. Armstrong’s iconic words, “That’s one small step for man, one giant leap for mankind,” marked a monumental achievement in science and exploration. The Moon landing united the world in awe and wonder, demonstrating what humanity could accomplish through courage, innovation, and collaboration. It expanded our understanding of space and ignited global interest in science and technology—inspiring generations to dream bigger and reach farther.

1970s

1970s

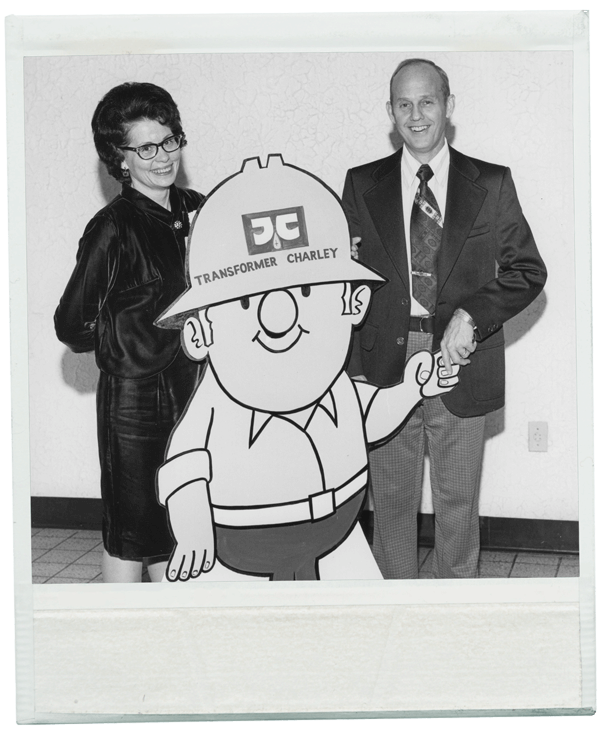

Introduction of “Transformer Charley”

Transformer Charley, used in SDMyers marketing and communications until the 1990s, helped spread awareness about transformer maintenance. Throughout the years, Charley has been featured in thousands of advertisements, brochures, truck graphics, training materials, and more. The early design drawings and concept for Charley were introduced by a marketing agency as an engaging, relatable side of the company. As we went to market under the name Transformer Consultants, a Division of SDMyers, Transformer Charley became the face of the organization.

1971

1971

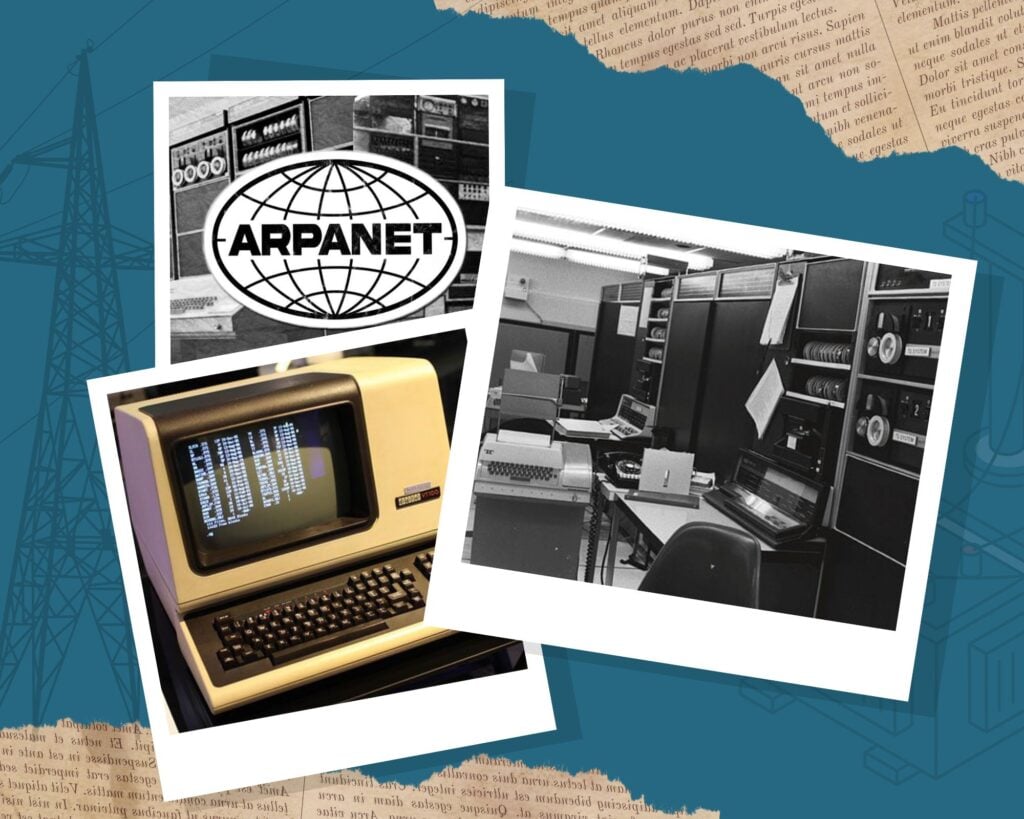

World EventFirst Email Sent via ARPANET

The first email sent via ARPANET—the precursor to the internet—was transmitted in 1971 by Ray Tomlinson. The message itself was a test, containing a random string of characters, but it marked a historic breakthrough in digital communication. ARPANET’s email function quickly became its most popular use, revolutionizing the way people and organizations communicated. It laid the groundwork for the global digital communications revolution, enabling faster, more efficient, and far-reaching connectivity that transformed business, education, and personal relationships worldwide.

1970s

1970s

Advancements in Reclaimer Rigs

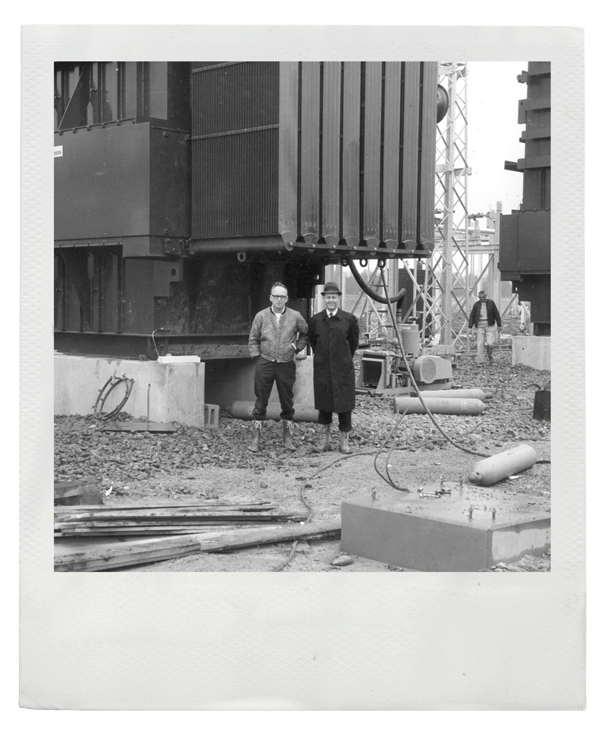

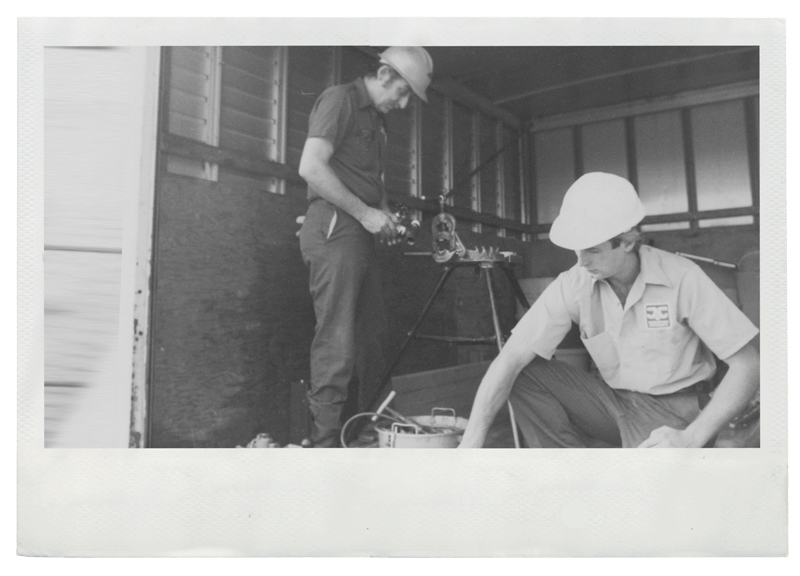

SDMyers continues to make advancements and innovations in transformer oil reclaiming rigs and oil dehydration units for service throughout the country. The company also expanded into “Live” bushing cleaning to deal with issues created by natural deposits and pollution within substations. Contamination from these often resulted in noisy substations, damage to insulating surfaces, partial discharge, tracking flashover, and loss of power.

1974

1974

SDMyers Nationwide Expansion

God’s faithfulness continues as the company expands its services to reach the entire US. The fleet of industry-leading oil testing and servicing operations expanded to include five oil “Re-Refiners,” now referred to as Reclaimers, and eight Mobile Test Laboratories (MTLs) serving industries and utilities nationwide. The company also began offering Electrical Testing services for transformers and breakers. The knowledge developed from the last ten years of study and research on transformer oil was now being used to inform the company’s approach to transformer reliability, testing, and maintenance. This approach continued Stan’s vision to support the customer with everything they needed for transformer maintenance.

1975

1975

Launch of Transformer Maintenance Institute

SDMyers established The Transformer Maintenance Institute (TMI) to educate transformer owners and technicians on best practices for maintenance. The information that was being collected expanded beyond SDMyers’ ability to share through traditional sales literature and office visits with customers. To facilitate the communication of this knowledge to a broader audience, Stanley founded TMI for training, education, and development of industry professionals. In that same year, TMI began producing the seminar “An Introduction to the Half Century Transformer”, which has been presented to customers in various industries worldwide.

1976

1976

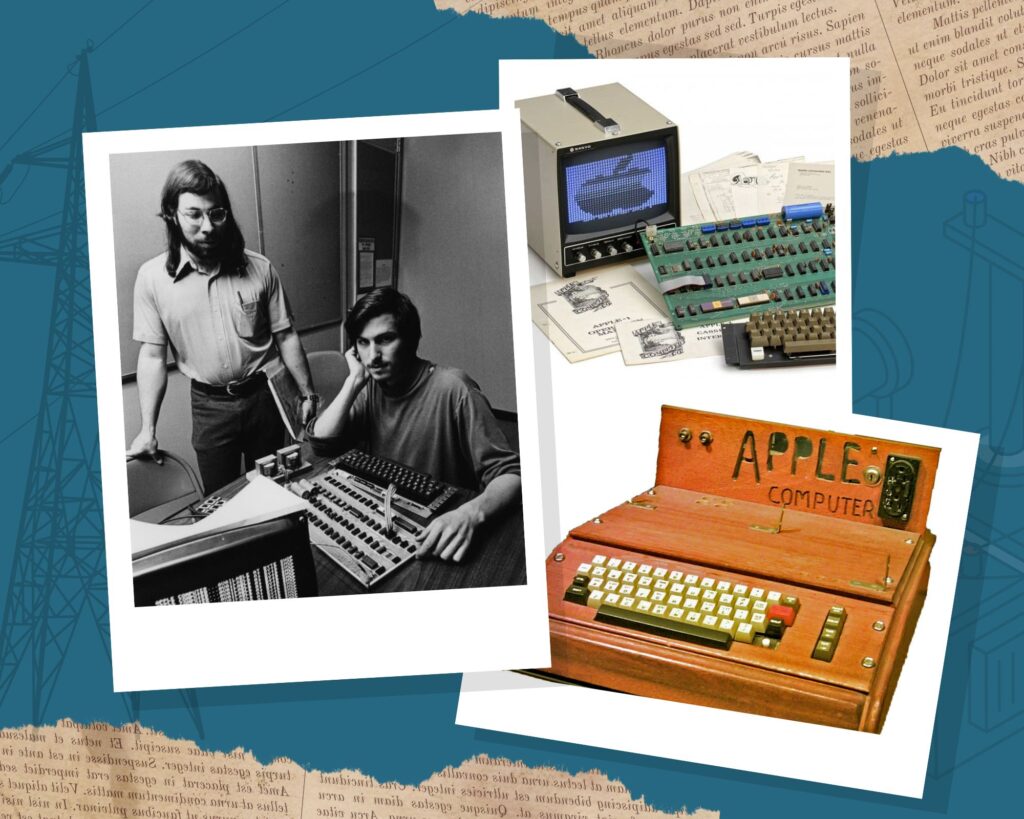

World EventApple Computer Founded

Apple Computer was founded on April 1, 1976, by Steve Jobs, Steve Wozniak, and Ronald Wayne in a garage in Los Altos, California. Their mission was to make personal computing accessible to individuals, starting with the Apple I—a hand-built computer kit designed by Wozniak. With Jobs’ vision and Wozniak’s engineering talent, Apple introduced the first highly successful mass-produced microcomputers. This early innovation set the stage for a company that would go on to revolutionize the technology industry. From the Macintosh to the iPhone, Apple continually redefined technological design, digital media, and mobile technology, transforming how people interact with computers, each other, and the world.

1977

1977

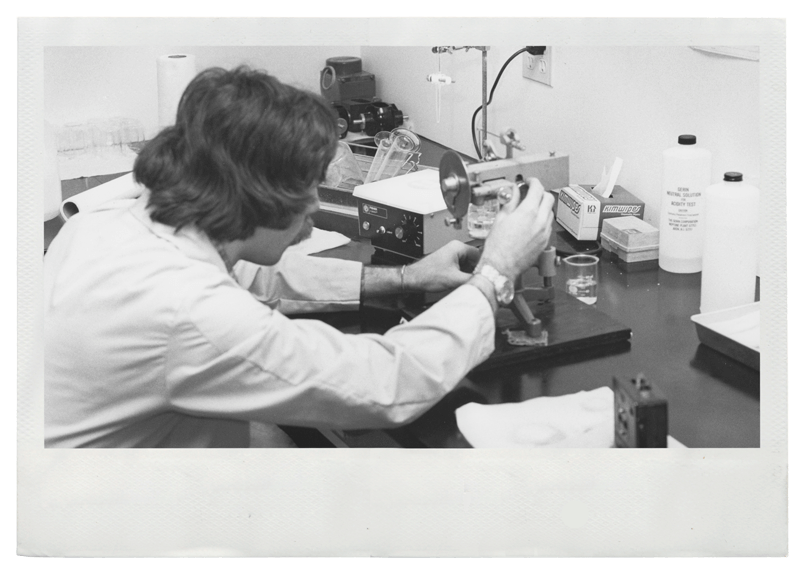

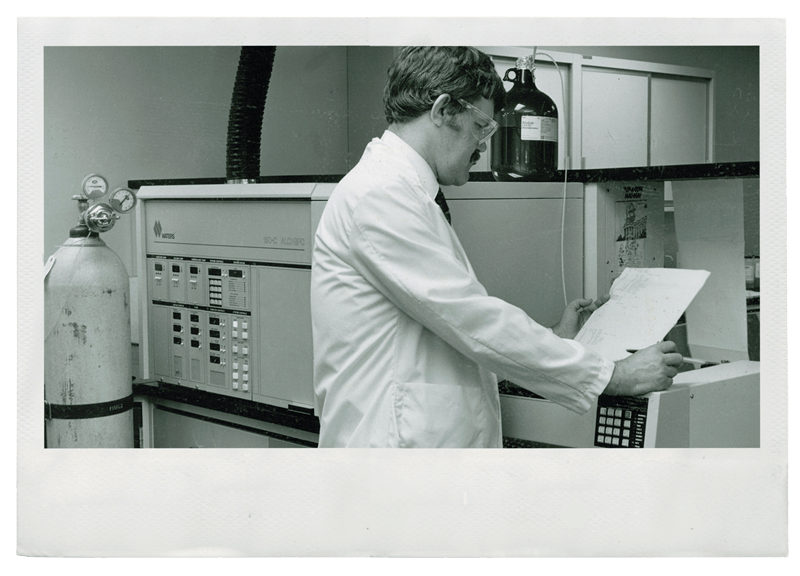

SDMyers Testing Lab Facility Opens in Cuyahoga Falls, OH

Stan continues to lead the organization with curiosity, research, and entrepreneurial risk as SDMyers establishes the first in-house laboratory for dissolved gas analysis and moisture-in-oil tests. This significant improvement provided a controlled environment for sensitive equipment not suitable for mobile operations. Transformer oil (also known as dielectric insulating liquid) plays a critical role in maintaining the reliability and safety of power transformers.

SDMyers’ in-house testing laboratory has grown with over five decades of experience and expertise. The lab, which began here in 1977, is staffed by transformer experts, PhD-level chemists, and trained technicians, offering a unique combination of analytical precision and transformer-specific insight. From the beginning, SDMyers focused on providing customers clear, actionable recommendations to extend equipment life and ensure system reliability.

1979

1979

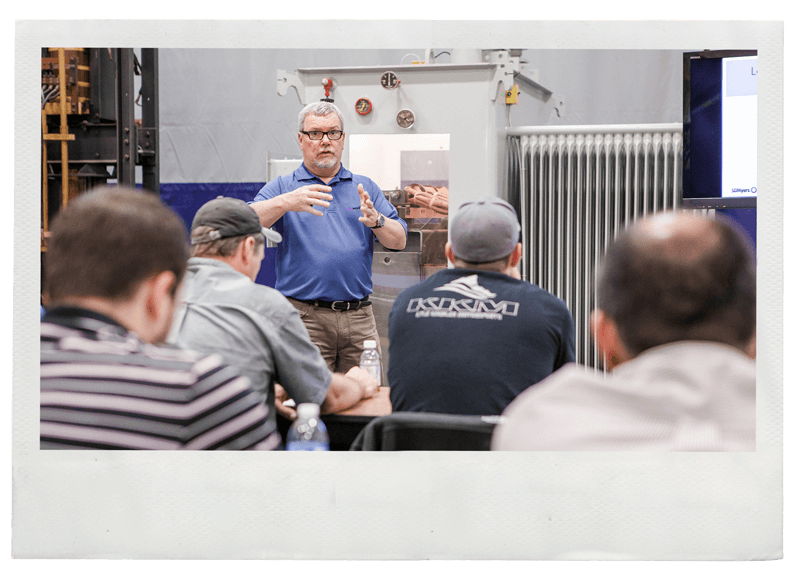

TMI Training Courses Grow in Popularity

The Transformer Maintenance Institute (TMI) emerges as the industry’s top provider of transformer maintenance training. As the go-to source for transformer maintenance education, TMI offered hands-on courses, seminars, and workshops to thousands of participants across the nation. Since 1979, training programs developed by SDMyers have equipped over an estimated 35,000 professionals, including electrical and reliability engineers, facility managers, maintenance supervisors, technicians, utility asset managers, and more.

These individuals have gained the skills and confidence needed to prevent failures, extend asset lifespan, and ensure operational uptime. This growth exemplifies our aim of valuing people and creating opportunities for them to reach their full potential. Currently, training is provided through our sister company, PowerPro 360.

1981

1981

Transformer Maintenance Guide Released

SDMyers publishes the first edition of A Guide to Transformer Maintenance. The guide is an end-to-end reference that covers the full asset lifecycle, from purchase and commissioning to preventive maintenance, troubleshooting, and responsible end-of-life planning. The book quickly became the trusted resource for maintenance leaders who need practical checklists, test interpretations, and decision frameworks—not just theory—to maximize reliability and ROI. In 2004, the third edition of the guide combined 39 years of field experience, detailing failure modes, fluid management, diagnostics, test thresholds, and maintenance intervals, all written for owner-operators who work to keep power on and reduce risk.

Today, work is underway on the fourth edition, expanding the guide with 60 years of SDMyers research, data, and hands-on experience—including millions of lab results and decades of field service insights.

1982

1982

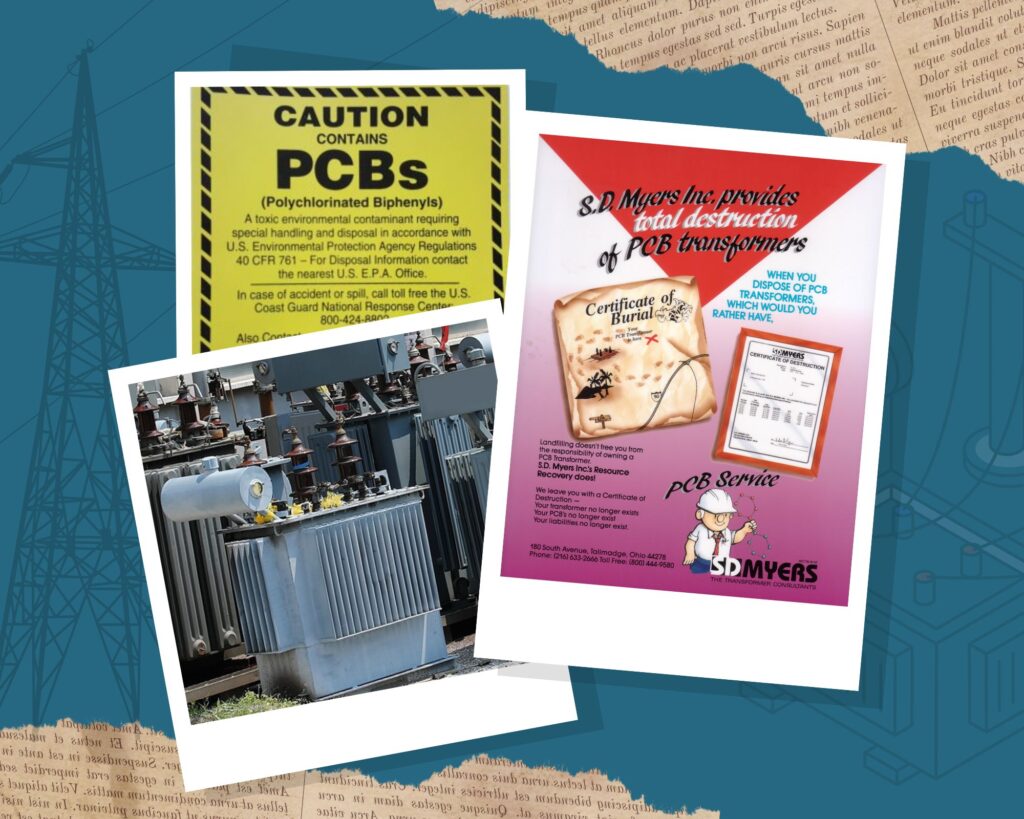

World EventNew Industry Regulations

In the early 1980s, the U.S. Environmental Protection Agency (EPA) implemented stringent regulations to control the handling and disposal of polychlorinated biphenyls (PCBs), toxic chemical compounds widely used in transformer oil. The EPA enforced rules that mandated careful labeling, recordkeeping, and containment procedures for any equipment containing PCB concentrations of 50 parts per million (ppm) or higher. The regulations required facilities to use certified disposal methods, including high-temperature incineration or chemical dechlorination, to prevent environmental contamination and human exposure. These actions significantly impacted the electric power industry by compelling utilities and manufacturers to retrofit, decontaminate, or replace PCB-laden equipment and ensure proper waste management practices.

1982

1982

PCB-Gone Process Developed

In the mid-20th century, polychlorinated biphenyls (PCBs) were widely used in electrical equipment because of their thermal stability and dielectric properties. However, this had significant downsides due to the persistence of PCBs and their harmful effects on health and the environment. By the late 1970s, regulations had become stricter, forcing owners to make tough choices—either retire otherwise healthy transformers or find a reliable way to eliminate PCB risks and remain compliant. SDMyers stepped in to fill that gap by developing a chemical treatment and processing workflow—referred to as “PCB-gone”—that removes PCBs from transformer insulating liquids, allowing units to be reclassified as “Non-PCB.”

SDMyers pioneered a practical, well-documented process that turned a complex environmental challenge into a trusted solution for owners. That dedication continues today, with PCB testing, data-backed verification, and proven field procedures that help keep transformer fleets compliant, reliable, and safe.

1986

1986

Headquarters Move to Tallmadge, OH

As SDMyers continued to grow, the company relocated to a larger 169,000 sq. ft. facility in Tallmadge, OH. The SDMyers legacy has never been measured solely by financial gain, technological progress, or the size of our building. It’s found in what we pass down—our faith, our stories, our values, and our witness. Moving into our larger space in 1986 allowed the company to continue blessing its employees, customers, and community in ways that honor God and serve others.

1986

1986

World EventSpace Shuttle Challenger Disaster

On January 28, 1986, the space shuttle Challenger tragically exploded just 73 seconds after liftoff, resulting in the deaths of all seven astronauts aboard. The disaster was caused by the failure of an O-ring seal in one of the shuttle’s solid rocket boosters, a flaw made even worse by unusually cold weather. This catastrophic event highlighted the inherent dangers of space exploration and exposed lapses in NASA’s engineering judgment and decision-making processes. The loss served as a sobering reminder of the extreme precision required in aerospace engineering and the high stakes of pushing the boundaries of human exploration.

1989

1989

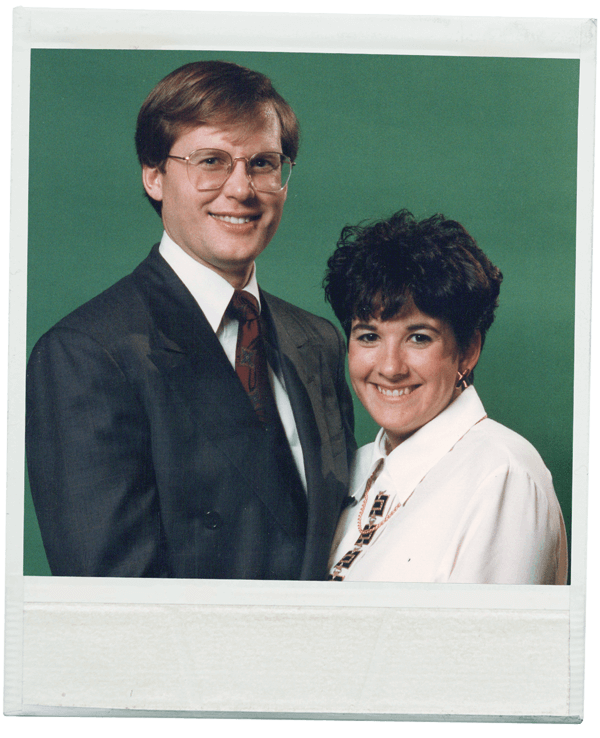

Dana Myers Succeeds Stan Myers as CEO of SDMyers

Dana Myers was chosen to succeed his father as the second CEO, carrying the legacy forward. Having grown up around the shop, the lab, and customer sites, Dana brought a deep, hands-on understanding of the work, the people who do it, and why it matters. Under Dana’s leadership, SDMyers doubled down on what makes the company unique—practical training, trustworthy diagnostics, responsive service—while modernizing how it is delivered: expanding data-informed decision-making, strengthening safety and quality systems, and broadening offerings across testing, field service, and reliability planning.

Where Stan had pioneered the path for nearly 25 years, Dana now took over as a second-generation steward of the organization, scaling the business with the same mission, heart, and passion.

1990s

1990s

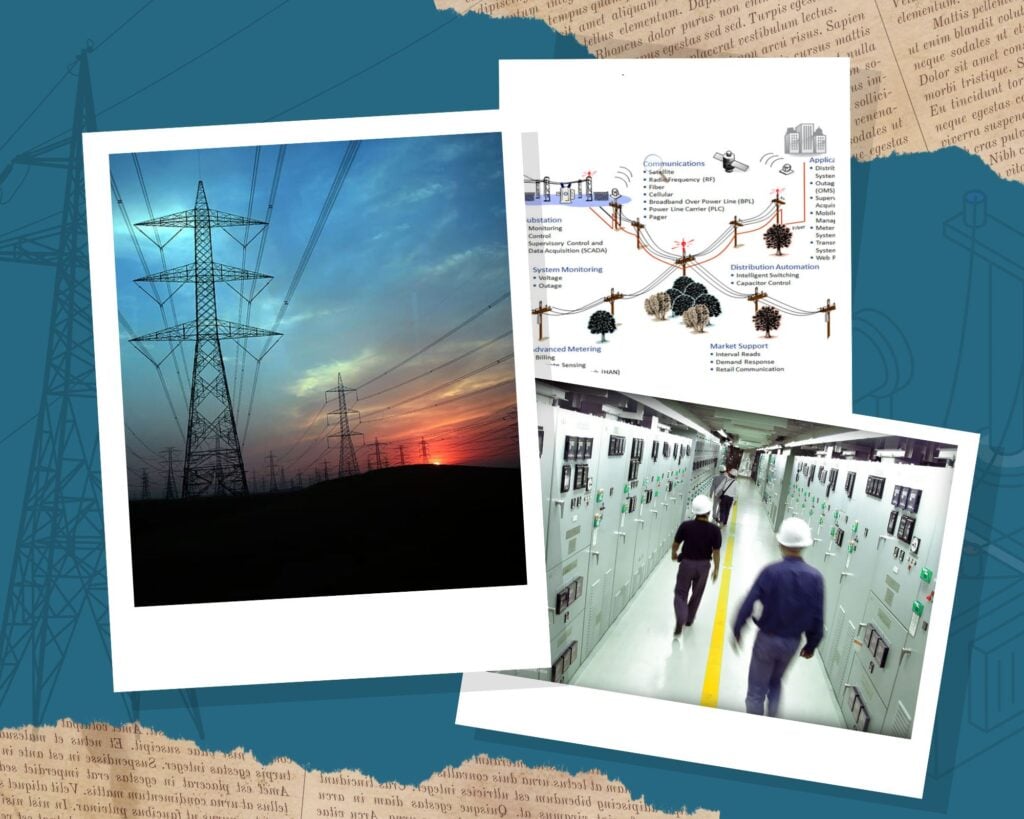

World EventSmart Grid and Digital Monitoring

The emergence of the smart grid and digital monitoring in the early 1990s marked a pivotal shift in electric power system maintenance. Advancements in sensors, communication technologies, and data analytics allowed utilities to move from reactive to predictive maintenance strategies. For transformers, this meant continuous monitoring of parameters such as temperature, load, and dissolved gases—critical indicators of performance and emerging faults. Digital monitoring improved reliability by enabling early detection of potential failures, extending asset life, and reducing unplanned outages. As the foundation of the smart grid evolved, utilities began leveraging these tools to optimize system performance, increase safety, and support more efficient grid management.

1990s

1990s

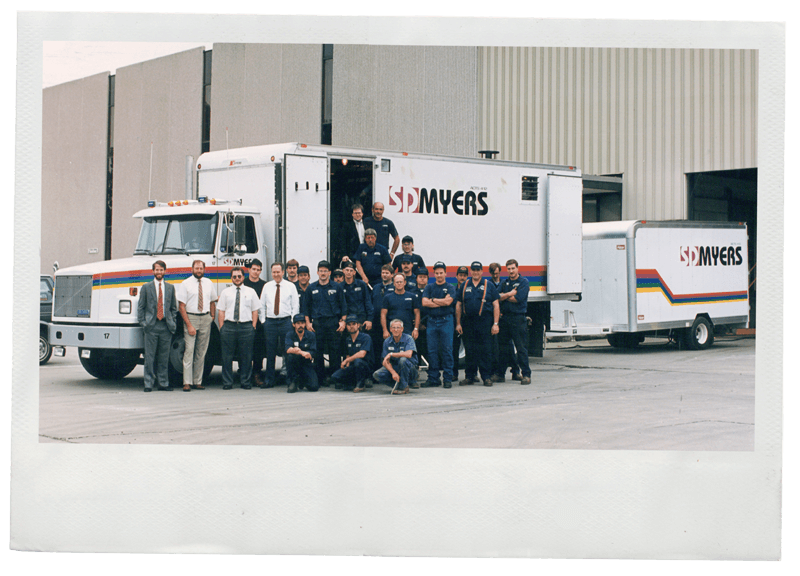

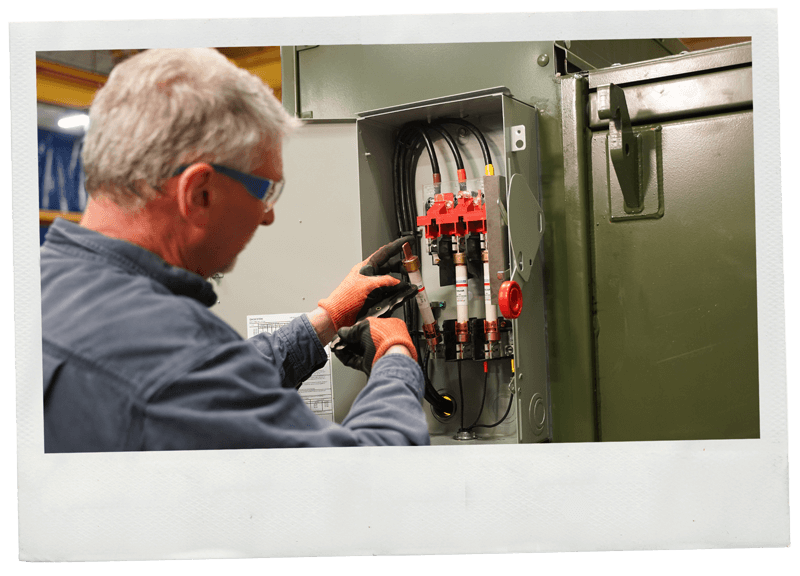

Growth of Mobile Fleet & Services

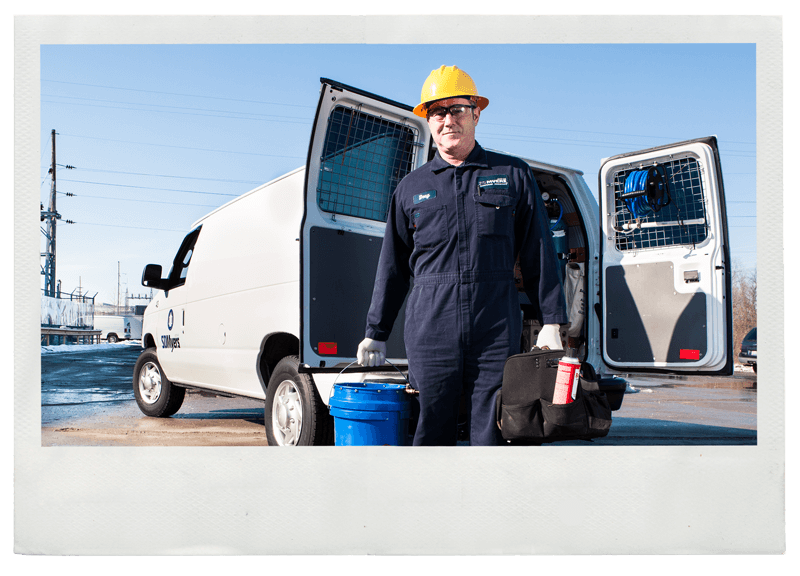

SDMyers continues expanding its mobile fleet and nationwide service capabilities. By heavily investing in a larger, better-equipped mobile fleet during the 1990s, SDMyers transformed on-site service into a true extension of its lab and engineering teams. Purpose-built rigs and trailers were standardized for safety and consistency, allowing crews to process oil, collect diagnostic samples, perform field repairs, and carry out electrical tests and inspections without removing units from service longer than necessary.

The coast-to-coast coverage by Field Service Crews and Mobile Diagnostic Technicians (MDTs), now known as Field Inspection Technicians (FITs), helped customers improve reliability and reduce downtime. The 1990s established the foundation for today’s trusted, reliable, and scalable field service and technician model at SDMyers.

1991

1991

World EventWorld Wide Web Goes Live to Public

On August 6, 1991, the World Wide Web became publicly accessible, marking a revolutionary moment in the digital age. Invented by British computer scientist Tim Berners-Lee, the Web was originally developed as a tool to help researchers share information more easily. Its launch opened the door to an entirely new era of global communication, transforming how people interact, work, learn, and entertain themselves. This pivotal innovation laid the foundation for the modern internet as we know it today.

1999

1999

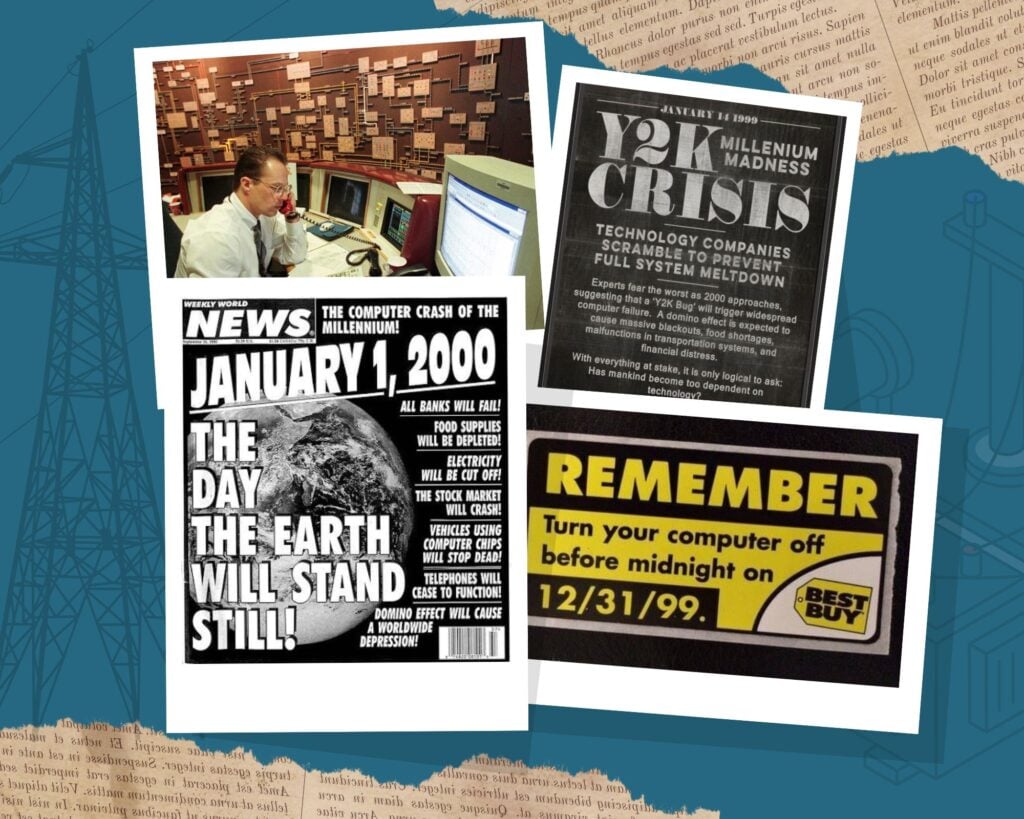

World EventY2K Hysteria

As the year 2000 approached, global concern mounted over the “Y2K bug”—a computer programming flaw that threatened to disrupt systems worldwide. Many older software programs recorded years using only the last two digits (e.g., “99” for 1999), raising fears that computers would interpret “00” as 1900, causing widespread failures in banking, utilities, aviation, and more. Governments and businesses invested billions in preventive updates and testing. As midnight struck on January 1, 2000, the transition proved largely uneventful, thanks to extensive preparation. While the anticipated chaos never materialized, the Y2K hysteria underscored society’s growing dependence on technology and marked one of the first major global IT challenges.

Mid-2000s

Mid-2000s

“Lab Online” Launched

When SDMyers launched Lab Online in the mid-2000s, customers finally had digital access to their transformer oil test history in one place—no more chasing PDFs or spreadsheets. Every sample result is organized by site, unit, and component in the portal, allowing teams to view trends over time (including DGA, moisture, acidity, IFT, dielectric strength, furans, PCB screens, and more). But access was only the start—the real win is context. Lab Online pairs customer test results with SDMyers’ expert assessment and diagnostics, helping transformer owners understand what each data point and result means, why it matters, and what to do next.

2003

2003

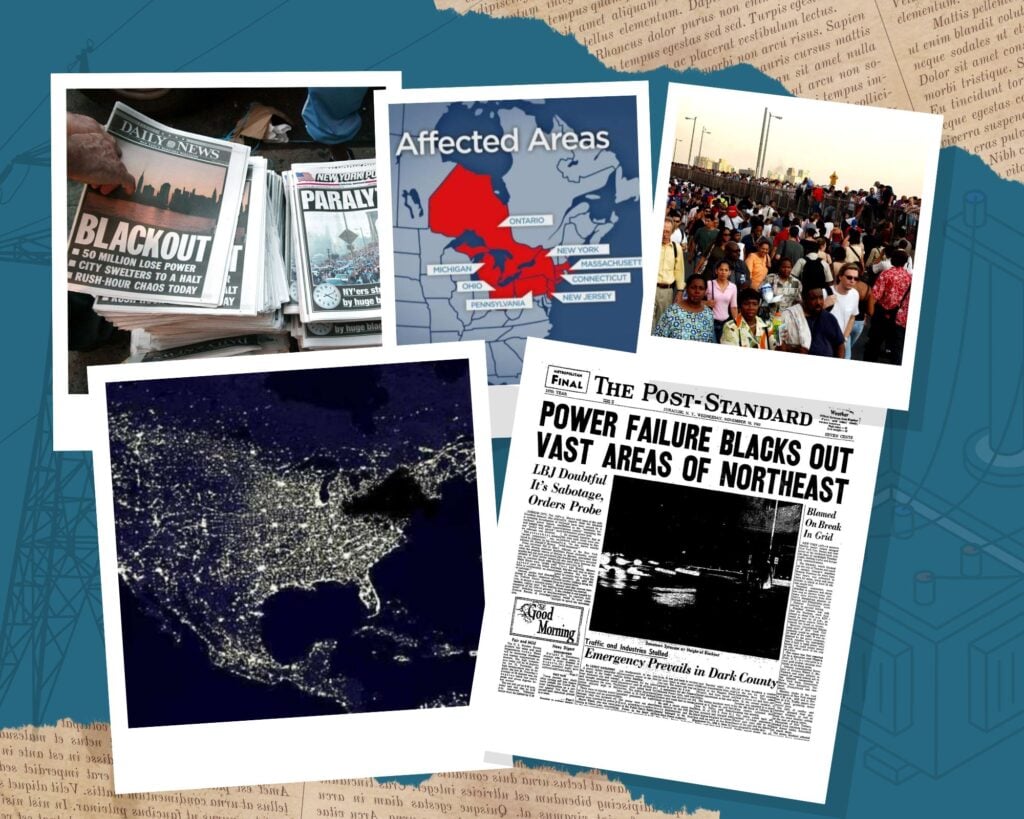

World EventMassive Northeast Blackout

The 2003 Northeast Blackout was one of the largest in North American history, affecting over 55 million people across eight U.S. states and parts of Canada. Triggered by a sagging power line in Ohio that came into contact with overgrown trees, the event led to a cascading grid failure due to outdated equipment and insufficient monitoring systems. The blackout lasted up to four days in some areas and resulted in billions of dollars in economic losses. This crisis highlighted the critical need for reliable electric power infrastructure and proactive transformer maintenance. Ensuring grid resilience through routine inspection, timely upgrades, and system redundancy is essential to prevent similar widespread disruptions in the future.

2004

2004

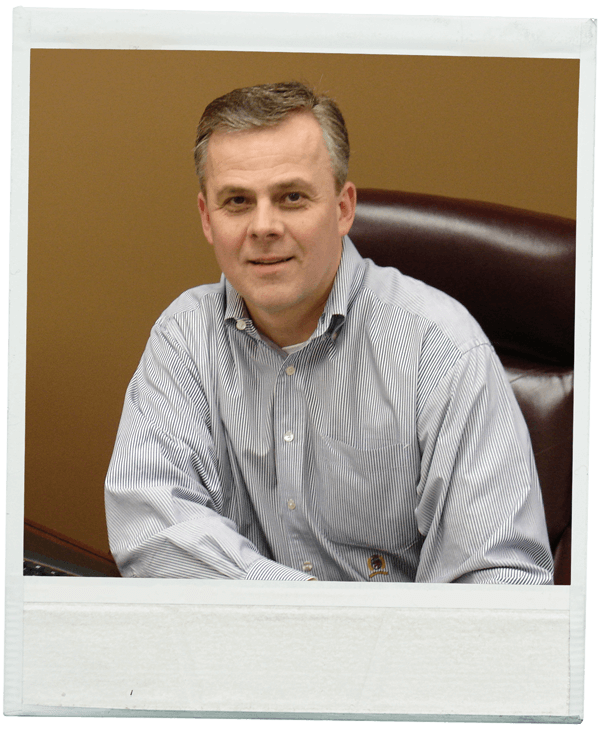

Scott Myers takes over as President of SDMyers

Scott Myers takes over as President of SDMyers, succeeding his brother Dana, and becoming the third within the Myers family to lead the company. Initially, throughout high school and college, Scott had no interest in working at his father’s company. However, after starting in a field service role, Scott saw how the company was making a difference. What kept him at the company was the people he worked alongside and the culture that was being built at SDMyers to serve customers with excellence and a deeper purpose. After more than 40 years with the organization, Scott has held numerous roles and positions. He currently serves as a Board Member at Good Place Holdings (the holding company of SDMyers) and is the author of Good Place Philosophy and Principles.

2005

2005

1st Spanish Edition of Transformer Maintenance Guide

The release of the first Spanish-language edition of the Transformer Maintenance Guide in 2002 marked a significant step toward making SDMyers training truly global. By providing the same practical checklists, diagnostic thresholds, and step-by-step maintenance procedures in Spanish, SDMyers’ training department was now able to empower utilities, industrial plants, campuses, and service partners by breaking down language barriers with a common playbook across North America and internationally. Instructors integrated the guide into Spanish-led courses and seminars, supported by visuals, glossaries, and scenario-based exercises that linked classroom learning to real-world troubleshooting and maintenance activities.

2009

2009

Relaunch of Field Service Division

SDMyers reestablished a dedicated field service team, bringing expertise directly to customers. The company focused on hiring, training, and developing a disciplined field service crew composed of veteran technicians and contractors. Growing the fleet and crew allowed for a more seamless approach to maintenance, repairs, and quickly turning diagnoses into action. This investment created a reliable, scalable operation that now completes over 400 jobs per year nationwide—from fluid processing and vacuum fills to electrical testing, inspections, and emergency response—delivering consistent, data-backed results wherever customers need support to keep their operations running.

2009

2009

SampleSafe Released

SDMyers introduced SampleSafe®, an external oil-sampling device that mounts on the outside of cabinet transformers so technicians can pull samples without opening the door—dramatically reducing exposure to energized parts and arc-flash hazards. SampleSafe is the safest way to obtain oil samples from cabinet transformers, supporting compliance with NFPA 70E guidelines. This innovative engineered product eliminates the need for bulky PPE or de-energization, helping to avoid shutdowns. The result is faster, safer, and more consistent sampling with added convenience and less risk.

2010

2010

TMI Becomes Training & Education

The Transformer Maintenance Institute (TMI) becomes the Training and Education (T&E) department. SDMyers continues to share its deep expertise in transformer maintenance and reliability with the professionals who keep power systems running. With a passion for empowering others, SDMyers has trained more than 35,000 students, equipping them with the knowledge and skills to make confident, informed decisions. Courses are grounded in decades of hands-on experience and real-world application, designed by experts who live and breathe electric power reliability. To this day, training continues through SDMyers’ sister company, PowerPro 360. Whether in the classroom, online, or on-site, the commitment to advancing the industry through education remains stronger than ever.

2010

2010

Dale Bissonette Becomes President of SDMyers

Dale Bissonette, formerly the CFO, began his role as President of SDMyers, where he served for over 10 years. As the fourth leader of SDMyers, Dale assumed the role as the first non-Myers President, serving the company through several years of growth and expansion. His leadership uniquely positioned the company to continue Stan’s vision for valuing people and operating under biblical principles and values. Dale currently serves as the Chief Executive Officer of Good Place Holdings and Executive Advisor & Senior Consultant with The Good Place Institute.

2012

2012

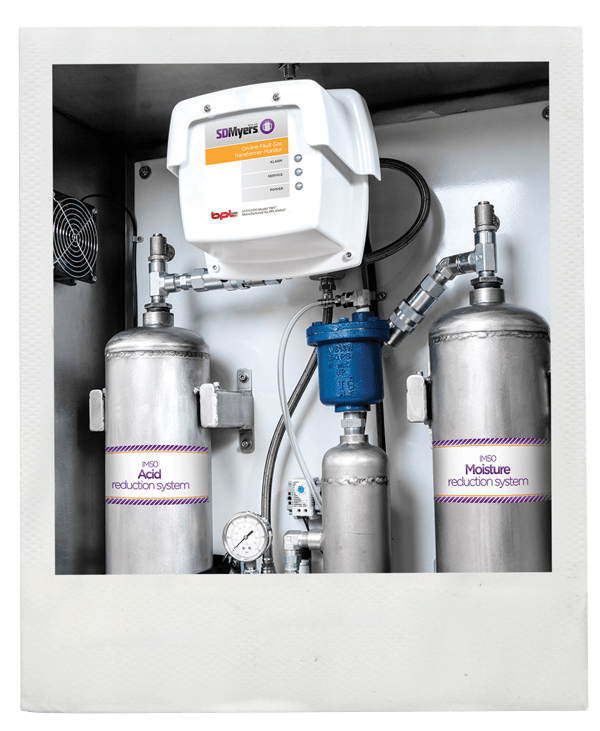

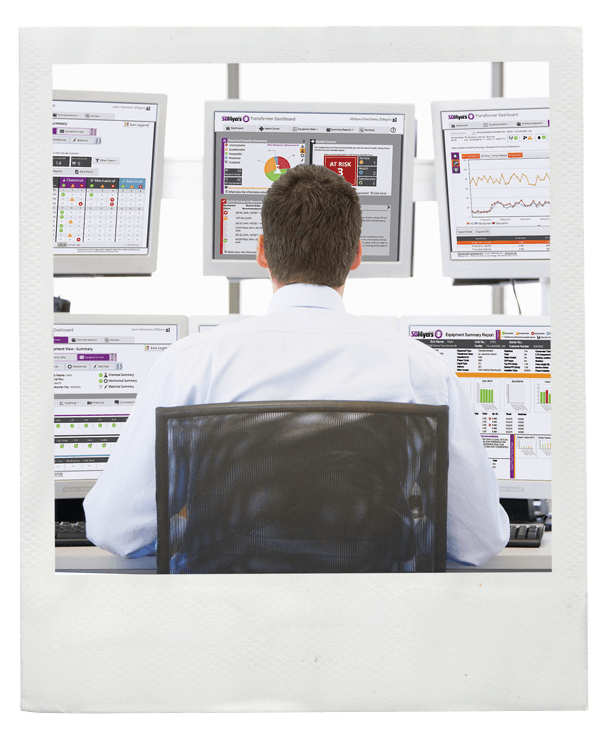

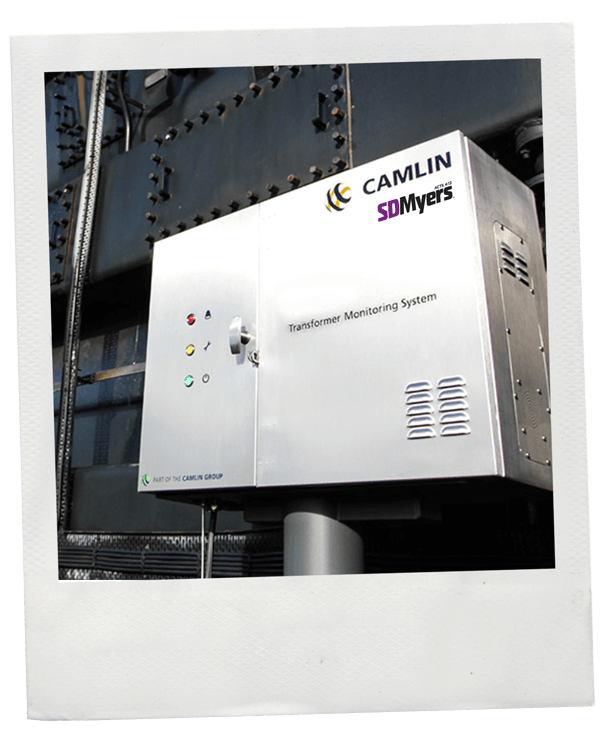

Guardian Monitoring Released

SDMyers introduced Guardian Monitoring®, a family of online condition monitors that stream transformer health data to Transformer Dashboard® and SDMyers transformer specialists for expert review and actionable alerts. The engineered product launch started with the G1 single-gas monitor (hydrogen for early fault detection) and expanded into the G5 five-gas unit (adding methane, ethylene, acetylene, and CO) and the G9 nine-gas system, providing full DGA for utility-grade visibility. Online condition monitoring offers an early fault detection method, allowing customers to move from reacting to failures to preventing them.

As with previous product launches, each decision to develop new technology builds on the history of delivering practical, data-driven solutions—engineering tools that turn complex transformer health data into clear actions, keeping equipment safe, reliable, and operational.

2013

2013

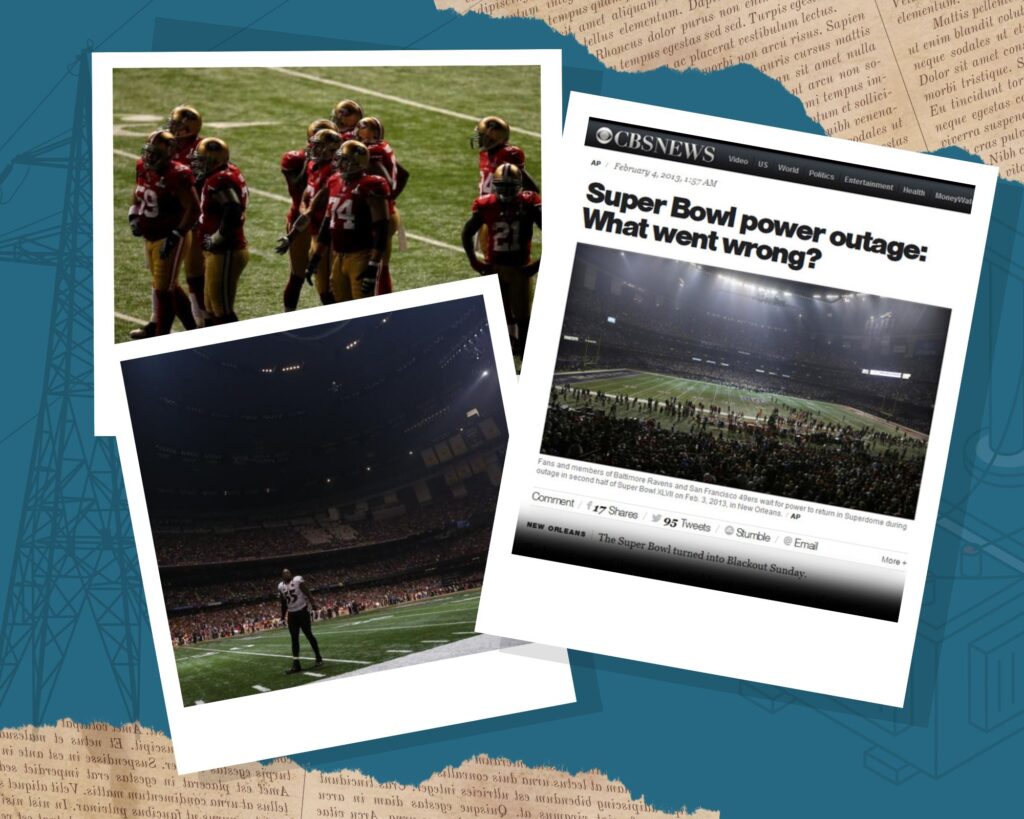

World EventSuper Bowl XLVII Blackout in New Orleans

During Super Bowl XLVII in 2013, a partial power outage at the Mercedes-Benz Superdome in New Orleans halted the game for 34 minutes. The incident occurred early in the third quarter and was later attributed to a faulty electrical relay device installed to protect the stadium from power surges. While backup systems prevented a complete blackout, the disruption impacted millions of viewers and raised concerns about the reliability of the electrical infrastructure at major events. The Super Bowl blackout served as a reminder of the importance of maintaining and testing power equipment, especially transformers and protective relays, to ensure consistent, uninterrupted power during high-stakes moments.

2013

2013

Growth of Mobile Fleet & Services

By expanding the MDT fleet and field service capability, SDMyers extends its reach to more regions, sites, and critical operations—reducing response times, increasing on-site capacity, and helping more transformer owners prevent failures and maintain uptime. Every additional rig and trained technician allows us to serve more customers with the same safety and reliability-first standards, multiplying our impact in communities and industries that rely on safe, uninterrupted power.

The growth isn’t about SDMyers’ intelligence, strength, or success, but about stewardship and responding to God’s faithfulness to our company’s mission and taking another step toward making the world a better place.

2015

2015

SDMyers Celebrates 50 Years!

SDMyers marked its 50th anniversary by reaffirming Stan Myers’ original vision—to honor God in our work, serve others with integrity, and make the world a better place through safer, more reliable power. The milestone was a celebration of God’s grace and goodness, and of the customers, employees, and communities who partnered with us along the way. Fifty years of purpose-driven service became a launching point for the next season of stewardship, utilizing SDMyers expertise to protect people, safeguard critical infrastructure, and pass on a legacy of reliability and care.

2015

2015

Good Place Holdings Created

The legacy Stanley Myers began in 1965 takes another step, ensuring the company remains committed to its deeper purpose. Founded on biblical principles, Good Place Holdings (GPH) is formed as a holding company to steward its organizations to see people flourish, organizations thrive, and communities prosper.

GPH is a holding company with no owners, investors, or shareholders. Typically, holding companies exist to control the ownership interest of other companies. They act as an “umbrella” or “parent” company, reaping the benefits of the profits. That is not how GPH operates. They turn that idea upside down by functioning as the roots of a tree, providing a firm foundation and supporting the well-being of their companies.

2019

2019

Camlin Energy Partnership

A strategic partnership is formed between SDMyers and Camlin Energy to enhance dissolved gas analysis capabilities through online condition monitoring. The Guardian Monitoring systems monitor the health of electric power equipment with exponentially more data than standard routine transformer oil testing. Additionally, when combined with Transformer Dashboard’s trend analysis and graphing capabilities, customers can plan transformer maintenance and minimize the risk of transformer failures.

2020

2020

World EventCOVID-19 Pandemic

The COVID-19 pandemic profoundly disrupted global business operations, forcing organizations to rapidly adapt to unprecedented challenges. Lockdowns, supply chain interruptions, and health concerns accelerated the shift to remote work, digital transformation, and e-commerce. Companies had to become more agile, embracing flexible work models, cloud technologies, and virtual collaboration tools. Crisis management and contingency planning became priorities, with an increased focus on employee well-being and operational resilience. The pandemic underscored the importance of adaptability and innovation, prompting businesses to rethink traditional practices and prepare for future disruptions in an increasingly interconnected and unpredictable world.

2020s

2020s

Retrofilling with FR3® and Cargill Partnership

SDMyers begins retrofilling with natural ester fluids and becomes an Authorized Service Partner of FR3® fluids with Cargill. Mineral oil has long been the standard liquid used in transformers. However, natural ester liquid, a vegetable-based dielectric fluid, has become increasingly common and accepted across the industry for its high flash points, grid resiliency, and sustainability.

2021

2021

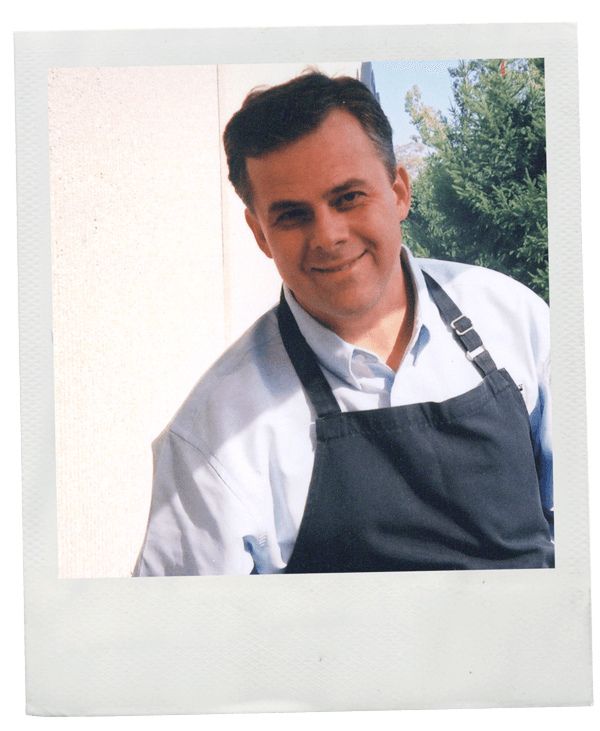

Jon Bucciarelli Becomes President of SDMyers

Jon Bucciarelli is named the fifth President of SDMyers, succeeding Dale Bissonette. With a career path that includes engineering and management at General Motors, teaching future engineers, and leading innovation at a bioplastics startup, Jon’s diverse experience and servant-minded approach to leadership make him a perfect fit to steward SDMyers’ 60-year legacy of curiosity, research, and serving others.

2021

2021

Expansion to Sacramento, CA

SDMyers has continuously answered the growing demand for reliable substations in industrial and commercial facilities across the continent. In 2020, we refurbished a processing rig to support our new field and service office in West Sacramento, California. While SDMyers’ offices in Ohio and California offer an expanded range of equipment, services, and expertise, Field Inspection Technicians (FITs) are strategically placed around the country to offer customers core testing, monitoring, and maintenance services. As customer needs have grown over the years, so have we, and we’re dedicated to providing holistic solutions for resilient electric power systems.

2024

2024

Fleet Reliability & Asset Refurbishment

SDMyers partners with organizations—big or small—to implement predictive maintenance best practices and transformer services that maximize uptime and fleet reliability. Additionally, SDMyers launches an asset refurbishment and partial restoration program for transformer services. Aging infrastructure, environmental factors, and evolving energy demands pose significant challenges to maintaining a dependable transformer fleet. Developing a backup plan is vital for resiliency. SDMyers leans further into its legacy of serving transformer owners in new ways with a holistic approach to fleet reliability, ensuring a stable and uninterrupted power supply across a transformer fleet.

2025

2025

60 Years of SDMyers

In 2025, SDMyers celebrates 60 years of service to its customers and the electric power industry. Since 1965, our legacy has been built on the dedication of remarkable people and the unwavering goodness of God’s grace. From pioneering transformer maintenance to leading the way in reliability and safety, we’ve never lost sight of what matters most: serving others, trusting God, and taking risks. Our success is rooted in a culture that values integrity, innovation, and stewardship. As we honor our past, we remain focused on the future—empowering our customers and living out our purpose for generations to come.

As we celebrate 60 years, we take our place as supporting characters in a much larger narrative—one that honors God by realigning with the way He created things to be: living beyond ourselves, building what’s good, and reflecting the character of the One who is truly good. It’s a legacy that sets us apart—a legacy marked by purpose, not just progress.

Leading the Next Era of Transformer Care

With a legacy of continuous advancements in transformer oil testing, predictive maintenance, sustainability, and fleet reliability, SDMyers is poised to lead the next era of transformer care.

Today & Beyond…

God’s grace and goodness have no end. Today and beyond, SDMyers remains committed to its aims and to extending transformer life, ensuring reliability, and pushing the boundaries of innovation. What we offer to our customers is a means to a much greater end: to glorify God through meaningful work, love for people, and the creation of good places where human flourishing happens.

This is the kind of legacy that lasts. This is the kind of legacy worth celebrating. This is the legacy we’re building.